LANES

Composition

Switch® lanes are made of a 10 mm thick laminate that complies with EN 438 and ISO 4586 norms. Thickness is achieved using sheets of craft paper impregnated with thermosetting resins. The resultant panel is then subjected to the combined action of pressure (9MPa) and heat (150°C - 302°F) in special presses in which the resins polycondense. The end result meets requirements set by Switch® and the USBC. These requirements include:

- Self-supporting properties

- Good dimensional stability and flatness

- High-impact resistance

- High resistance to wear

- High resistance to chemical and organic solvents

- Excellent resistance to fire

Technical Data

When designing a new building, the structure should ideally have a clear span in the bowling equipment area. The ceiling height should be at least 3.05 meters.

Bowling centers require specific heating, air-conditioning and electrical specifications. It is strongly recommended to discuss these requirements with a professional before proceeding.

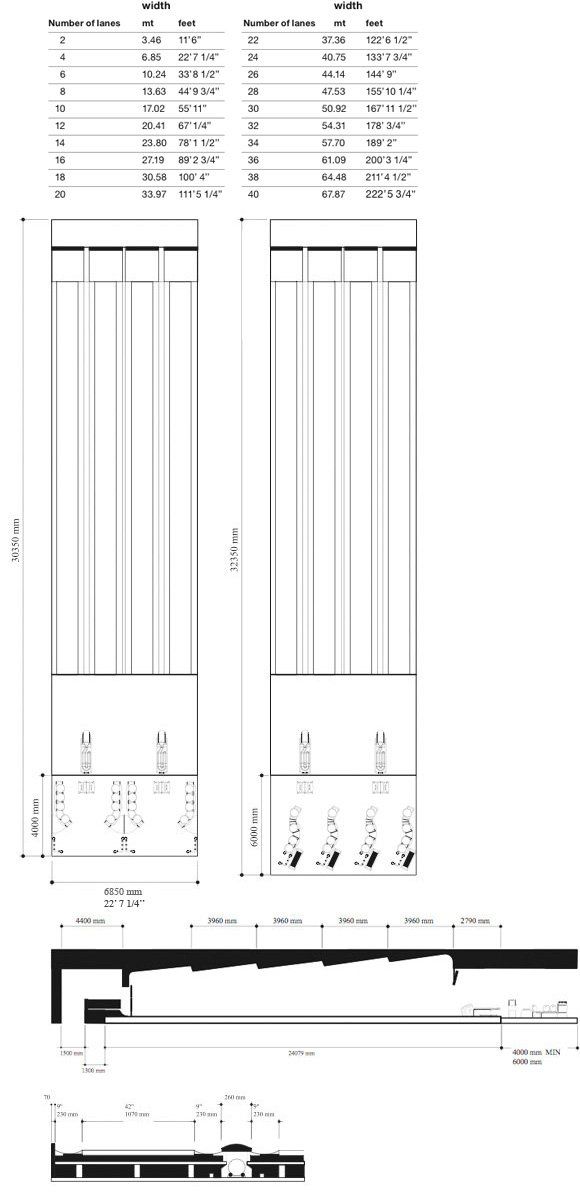

To determine the size of the building, use the bowling lane width chart once you have selected the number of lanes you are intending to install. You should then deCATe what other facilities you would like to provide, such as reception, snack, cafeteria, children's area, amusement machines, billiards and meeting rooms.

Within the limits of the possibilities, always include side aisles, known as service aisles, on each side of the bowling lanes. The length is determined by using the length of the bowling lanes (25.38m), including machines, lanes and approach. Then add a recommended (1.50m) clear service passage behind the pinsetters and finally add a minimum of (4.0m) for a standard bowlers' seating area.